By Ross Kuhre (Stock 93 MX-5, C package,

130k mi)

If you have an idle

problem with the unmodified NA 1.6L engine, this article is intended to help

you understand how the ISC (Idle Speed Control) system should work

and how it may fail (my experience). If

you isolate your problem to the ISCV (Idle Speed Control Valve) this article

may also help you find replacements or in special cases, make repairs.

If

you are just curious about how the ISCV operates and is constructed you can

jump to the VALVE OPERATION section at the end of the article.

Abbreviations & Acronyms: It was my intention to only define them the

first time they are used.

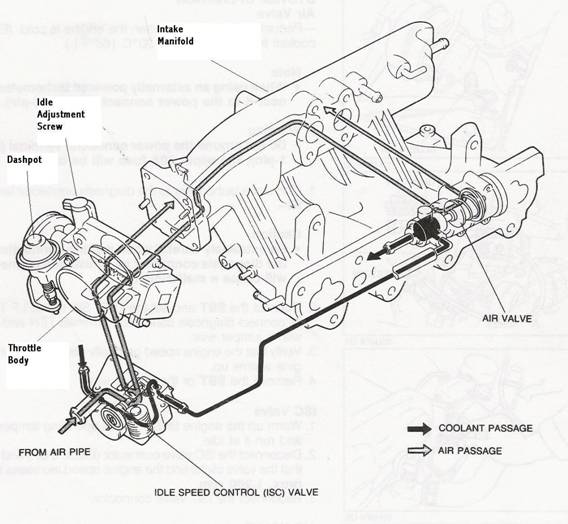

System Description

The ISC system has two components exclusively

dedicated to idle air / rpm control. Those

are the ISCV and the AV (Air Valve). Other components play roles in the idle rpm,

including the IAS (Idle Adjustment Screw), which is part of the throttle body.

This screw may or may not be under a “Blanking Cap”.

The IAS is a simple air bypass needle that controls air in a passage

around the TB (Throttle Body) butterfly valve.

This path is separate from the ISCV & AV paths.

The

Miata Workshop Manual has the following description

with this diagram. “To improve idle

smoothness, the ISC system controls the intake air amount by regulating (the)

amount of the by-pass air that passes through the throttle valve. This system consists of the air valve that functions

only when the engine is cold, the ISC valve that works throughout the entire

engine speed range, and the control system.”

The

“control system” mentioned in this description is primarily the ECU (Engine

Control Unit). Normally, with input

signals from Ignition rpm, Temperature, Throttle Position, and Air Flow sensors,

the ECU operates in a control loop and adjusts several engine components including

the ISCV. A signal to the ISCV from

the ECU controls the amount of bypass air into the intake manifold and thereby

the idle rpm. It is possible

for bad rpm and temperature sensor inputs to create bad ECU commands to the

ISCV. However, when the DC (Diagnostic

Connector) TEN & GND contacts are shorted together for Self Diagnosis

and troubleshooting the ECU control loop is opened. With the control loop open, the ECU ignores

inputs from Ignition rpm, Temperature and Throttle Position sensors and sends

a fixed signal to the ISCV. This should

produce a stable idle value for troubleshooting & fault isolation. (More on that later) Here’s a Picture of the complete ISCV.

The other dedicated ISC component is the AV (picture later).

The AV is a “Dumb” device. It is simply a wax pellet driven thermostatic

valve. When working correctly it gradually

closes its idle air bypass ports to the IM (Intake Manifold) as the

coolant flowing through it comes up to the full engine-operating temperature.

WARNING: THE READER

IS ADVISED THERE ARE HAZARDS PRESENT WHILE DOING THESE PROCEDURES. THE READER TAKES FULL RESPONSIBILITY FOR DAMAGE

OR INJURY TO ANY PERSON OR PROPERTY INVOLVED.

Trouble shooting:

I

suggest you read completely through each section before taking any action.

Here

is a brief description of my failure symptoms.

I suddenly began having erratic idle rpm behavior. The symptoms varied from dying at idle, idling

around 2k rpm and anything in between including normal rpm. The symptoms did not often remain the same for

long periods. I found that if I stopped

the car, turned off the key and restarted the engine, the symptoms would often

change. The engine ran normally at

highway speeds. In the end, I discovered

I had 2 problems.

1. I had a dirty (Gummy)

ISCV. My ISCV had not been cleaned

for at least 70K miles.

2. I also had an intermittent

& varying high resistance failure at the ISCV Solenoid (approx 60 to 180

ohms). After I cleaned the ISCV the

dying at idle symptom disappeared. At

first, solving the grunge problem led me away from the ISCV, thinking I had

eliminated any problems there. Furthermore,

my ISCV passed the “Click” test, which you may read about elsewhere.

Therefore, I consider the “Click” test inconclusive.

After the ISCV was cleaned my idle rpm values were high, unstable or

normal. The dying symptom disappeared.

Here

is my suggested troubleshooting approach:

To Start, I will assume you had a normally running and idling engine.

Suddenly, for no apparent external reason, the warm engine will

not idle consistently at the correct rpm (800-900 rpm).

Fight the normal urge to immediately adjust the IAS.

This action might temporarily seem to correct the problem but will

probably only mask the real problem. Find

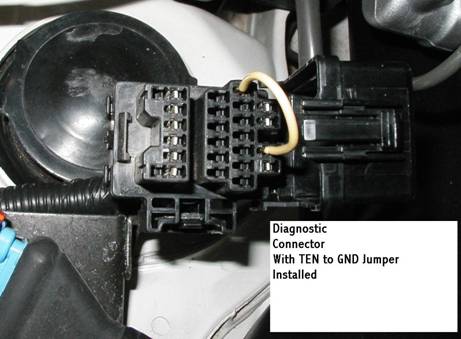

the DC next to the engine, above the upper shock absorber mount on the driver’s

side of the car. See the picture below.

Warm

up the engine to operating temperature. This

value has always been near mid scale on my Temperature Gauge. Turn off the heater & A/C blower

controls inside the car. If you’ve

had A/C trouble you should probably confirm the A/C clutch is also not

engaged. On a pad, note your current

tachometer idle rpm value. If it is

unstable note the range of values. With

the engine still running at idle, connect the TEN & GND contacts in the

DC (14 awg solid copper wire worked for me). Note the 2nd tachometer rpm value. Do not make an adjustment of the IAS at this

time. If your engine will run smoothly

with the throttle held slightly open but will die or not idle at 800

rpm or higher, move to the Cleaning part of this article.

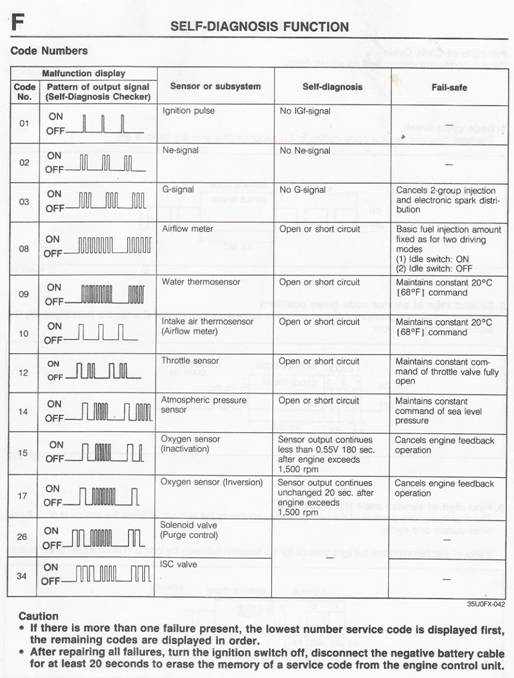

Shorting the TEN to GND contacts in the DC enables

the Self Diagnostic feature of the ECU. If

you are lucky you will have a blinking error code being displayed by your

instrument panel Check Engine light. Below

is the table from the Miata Workshop Manual to decipher

what these blinking error codes mean. For example, if you have an open coil in your

ISCV you should see 3 long blinks followed briefly by 4 short blinks. This is the 34 error code, indicating a problem

with the ISCV. This code will repeat

over and over. I had no error codes

displayed. Note the remark at the bottom

of the table that says you will need to remove the Negative battery terminal

to get this code to disappear after you repair a failure. I found this was not always the case. For example, when I removed the ISCV connector

creating a “simulated” Open ISCV solenoid or broken wire from the ECU to the

ISCV, I only needed to reinstall the connector and the 34 error code disappeared.

However, I did have to remove the Negative battery cable to clear a

09 code that I set by removing the connector on the Water Thermosensor. Technically, when I “opened” the Water Thermosensor, I got what appeared to be a 19 error code (One

long pulse followed by 9 short pulses). I have no explanation for this apparent

table discrepancy but the reader might be on the lookout for other code mysteries

like this. Obviously, since I had

created this “error” condition on purpose and there is not a 19 code in the

table, I disregarded the discrepancy. There may be a logical explanation and some

reader smarter than I will probably inform us about that, later on this site.

Sorry, I don’t have a comprehensive list of which codes are cleared

without removing the Negative battery cable.

Try the easy way first then remove the Negative battery cable if necessary. By the way, it does need to be the Negative

cable. NOTE: Be sure to have

the Positive battery terminal well covered as you may be reaching across the

battery with a ratchet & socket extension to get to the Negative terminal.

This process creates the real risk of shorting the battery.

That is a dangerous event. I

covered the Positive terminal and then still chose to use a short 10mm open-end

wrench that was not long enough to reach from terminal to terminal.

If

you do not discover any error codes continue from here. Check for any cracked or loose vacuum tubing

that is connected to the IM. Check

both ends of the tubing or, if the IM end is good, pinch off

the tube temporarily with pliers to see if a change in idle rpm occurs. A decrease in rpm means air was passing through

that line. In my case, this process

revealed I had a small leak in my PCV valve. Unfortunately, after replacing the existing

PCV valve twice, I found the original one had the smallest leak of the three.

So, for the time being I chose to leave it in and temporarily accept

a 50-rpm increase in idle speed. This leak was obviously not my core problem.

Next,

turn off the engine and eliminate the AV as the culprit. Once the engine is warm the AV should close

and allow no bypass air through it, into the IM. There is a workshop manual procedure to remove

the AV, Freeze it, mark its shaft, then Heat it & confirm the valve shaft

moves and is closed when Hot. If

you choose to do this you will need to deal with the coolant that is in the

AV coolant lines. I simply pinched

off these tubes with small clamps or a small smooth flat jaw vise grip pliers.

If you want to perform this test, install these clamps just

far enough away from the AV to give you space to move the hose clamps back

off the AV metal coolant tubes. Put a rag under the AV, as you will have a small

amount of coolant trapped in the AV when you remove it. Because I had intermittent symptoms, I chose

to reinstall the AV with a DEG (Dead End Gasket) to totally eliminate

the chance that the AV was occasionally sticking and allowing idle air into

the intake system (see the picture). NOTE: If you let the engine cool with this gasket

in place, you will need to manually hold the Throttle open until the engine

warms to operating temperature if you re-start the engine.

You

can fabricate this temporary DEG from common gasket material as I did.

Install it between the AV and the intake manifold.

When you reinstall the AV be sure the factory O-ring gasket stays on

the AV side of the DEG. It is not necessary to disconnect the coolant lines

to make and install this gasket, as only air passages are open when the AV

is separated from the IM. The four 8 mm mounting bolts have a recommended

torque of 43-69 in. lb. While you have

the AV removed for either procedure, clean the air passages with throttle

body cleaner. NOTE: Remove the

rubber O-ring gasket before cleaning the AV. Some cleaners may distort the rubber and cause

it not to fit correctly. If the gasket

is in poor condition and possibly leaking, replace it. If you have not localized the problem continue.

Leave

the TEN & GND jumper IN. Do not

touch, tap or disturb any components under the hood. Restart the engine. Note a 3rd tachometer value. Stop the engine, pause about 10 seconds then

start the engine again and note the 4th tachometer value. While the engine is still at idle, remove the

TEN, GND jumper. Note the rpm value

again. Now you should have 5 tachometer

readings. If readings 2,3, & 4 are not equal and/or not between the 750 &

1K marks on the tachometer, it is very likely either the ISCV or AV (if you

did not isolate it) is the culprit. The

first remedy I would try is cleaning.

CLEANING:

A first non-invasive cleaning can be attempted

by spraying throttle body cleaner (I used Berry B12 carb.

& TB cleaner) into the air supply tube to the ISCV with

the engine running. It is possible

to remove the front end of this tube near the throttle body and seal the black

molded plastic intake air chamber port with a cork. (see picture)

When

spraying the cleaner you may need to keep the engine from dying by hand controlling

the throttle control on the side of the Throttle Body.

After

this external cleaning, remove the cork and reinstall the air tube to the

ISCV. Now redo the idle check outlined

above. If the second set of values

are still incorrect but not the same as set #1 (at the same Temp.), I suggest

you remove the throttle body, remove the ISCV and clean them directly with

throttle body cleaner. NOTE:

When using the cleaner do not spray the rubber O-ring gasket.

Some cleaners can distort this rubber so it will not be reusable. You

will need to remove only the TB end of the black air chamber tubing that runs

from the air cleaner to the TB. The

rest of the air inlet tubing needs to be loosened but not totally removed. TB removal requires the removal of only 2 bolts

and 2 nuts (12mm). A 3rd

bolt (10mm) holds a piece of the air tubing below the TPS (Throttle Position

Sensor) connector. Disconnect the throttle

control cable from its attach point on the side of

the TB. This is done by manually rotating

the throttle wheel to full open (CW). Then,

with the cable slacked, remove the cable end through the slot on the side

of the throttle wheel. You also need

to remove the inlet air tube that is connected to the ISCV. When you get the TB free remove the ISCV &

TPS connectors. If the vacuum line

from the Cruise control is installed you will probably want the TB end of

it removed also. You will need to disconnect

the coolant lines attached to the ISCV. You can simply pinch off these lines close to

the ISCV (as detailed for the AV) or drain coolant from the system until it

is below the ISCV level. In either

case there will be some coolant to catch with a rag from the hoses and valve

when you make the final separation. Separate

the TB and ISCV by removing the 3 screws holding them together. Watch for the O-ring gasket and set it aside. While you have the TB removed clean it carefully

without removing the factory seal material, which is around the rim of the

butterfly valve and seat. Confirm the

Butterfly is not sticking and is fully closed at rest. This might be a good time to confirm the dashpot

(see first Diagram) is not preventing the throttle from closing completely. It should cause the throttle to slow when it

first makes contact but not keep it open after that initial delay. If the throttle valve remains open and the dashpot

is not to blame, look for and determine whether the throttle stop screw is

at fault. If so, adjust it to touch

the throttle stop plate at the zero open position. I used a strip of printer paper and set the

stop screw so the drag just barely let me pull the strip out without tearing

it. Clean the rotating valve area inside

the ISCV and confirm the shutter valve rotates freely but returns to a position,

open about 20%. (see pictures in VALVE OPERATION section) While you have the

ISCV removed, use an ohmmeter to measure the resistance between the pins on

the connector. The Miata

Shop manual calls for a value of 12 +/- 1 ohm.

Remember to adjust for the resistance of your meter leads. If you have a resistance of 0 or below 11 ohms

you probably have a short between windings in the ISCV solenoid. Double & triple check yourself here to confirm

you are not shorting your leads as you probe the connector pins or have a

defective meter. If you do indeed have

a shorted or low resistance reading, I think you should look for a replacement

ISCV. (See REPLACEMENT section) If

you have a reading higher than 13 ohms you probably have an open wire or high

resistance connection in the solenoid. If

you can, use test leads with alligator clips to connect your meter to the

connector pins. (See picture in REPAIR

section) While you have this static

connection, tap the black body of the ISCV around the coil and connector with

the plastic handle of a screwdriver. If

you don’t have the alligator test leads, try to clamp the ISCV in a vise (carefully!)

so you can have both hands free to accurately touch the probes to the pins

when you take resistance readings. If

your resistance reading changes after a tap, it is possible you have a repairable

problem. (See Repair section) This

is where I found my 2nd problem. I had an intermittent & varying high resistance

reading of about 60 to 180 ohms. Your

readings will likely not be the same as mine or may even be “Open or infinite”.

ADJUSTING

THE IAS. If

you have cleaned &

checked the TB, the ISCV, and the AV per the preceding steps and have found

and corrected a problem, I would now reassemble the parts & adjust the

IAS to 850 +/- 50 rpm with the TEN & GND contacts shorted in the DC. Ideally the rpm will be the same (850 +/_ 50

rpm) with or without the TEN & GND jumper installed.

REPLACEMENT:

If you localize your problem to the ISCV as I did, you have

several options.

1. You can search the net

or contact dealers for new parts. I

did a search on the net and found the cheapest new ISCV I could find

cost $514.00. If this seems reasonable

to you, order and install that ISCV. OH

yeah, and send me your old one!!

2. You can also do a search

of salvage yards on the net. I found

several sources for a used ISCV. All

the used sources I found sold the ISCV as part of the Throttle Body. This might be a way to pickup a spare TB if

you are into stocking “spare” parts. The prices I found for this used part

ranged from $75 to $250(+ shipping ). Some sites showed a 30 day guarantee on their

parts. I would try to get this guarantee

specified for the ISCV. Some places

have a disclaimer that excludes Electrical parts and this would likely be

in that category.

3. You can also go to local

Salvage yards to search for a used unit. I

could not find any used Miatas in my area salvage

yards. However, I found a “You Pull

It” yard which had an early 90s era (sorry exact yrs unk)

Mazda Protégé with the engine dumped in the rear seat. Earlier, on a Miata.net forum I had read a post

that said the ISCV was interchangeable between the NA Miata

and some Protégés. As noted in that

post the Protégé ISCV has different cooling tubes.

I worked around this by buying new 5/16th ID tubing and

running longer coolant line(s) to/from the ISCV. The used Protégé ISCV was available for $20

+ tax. I think I got lucky!! Before I pulled the ISCV I took a resistance

reading and found a solid 12 ohm +/- 1 ohm value at the connector. I suggest you also ask any mail order source

of used parts to take this resistance measurement before you have them send

the part. I pulled the used unit and

also took the O-ring seal and the in/out coolant tubing. One of these coolant lines was useable in my

Miata for the line between the ISCV & AV. The used unit I bought needed to be cleaned

of Gummy carbon before it functioned properly.

I installed the used unit. (ISCV

to TB screws, 25-35 IN.-lb) & (TB to IM bolts, 14-19 ft-lb) The gasket between the TB & IM was broken and needed to

be replaced. I found one at my local

Auto Zone, P/N 60874 for $2.99. (I

have no local Mazda dealer)

ADJUSTING

THE IAS. If

you have cleaned &

checked the TB, the ISCV, and the AV per the preceding steps and/or have found

and corrected a problem, I would now reassemble the parts in reverse order.

Start the engine and warm it up. Adjust the IAS to 850 +/- 50 rpm with the TEN

& GND contacts shorted in the DC. Ideally

the rpm will be the same (850 +/_ 50 rpm) with or without the TEN & GND

jumper installed. You should be ready

to go zooming, unless you need to clear an error code or take out the trash!!

REPAIRS

??: Now

the fun begins!

Having an “abnormal” curiosity and having repaired other

potted modules in the past, I decided to attempt the repair of my “bad” ISCV.

Later, I also decided to disassemble the unit to learn how it operated

and was constructed. I already had a fully functioning replacement

installed so there was no real pressure. Following

is a description and pictures of that repair process. NOTE:

This process can very easily result in an ISCV with an open resistance

solenoid. This should not leave you

any worse off than your failed condition. However, if you are not prepared

to replace this unit with one from another source do not proceed. Furthermore, if you have any hope of using the

ISCV again, do not disassemble it as I did.

There are virtually no repairable parts inside the ISCV body. Instead, see the VALVE OPERATION section where

I have already disassembled the valve for our enlightenment.

Remember,

my failure symptoms were a varying high resistance condition and usually changed

as a result of my tapping the ISCV solenoid module.

From past experience I suspected the problem

might be a bad connection or broken wire at the rear of the male connector

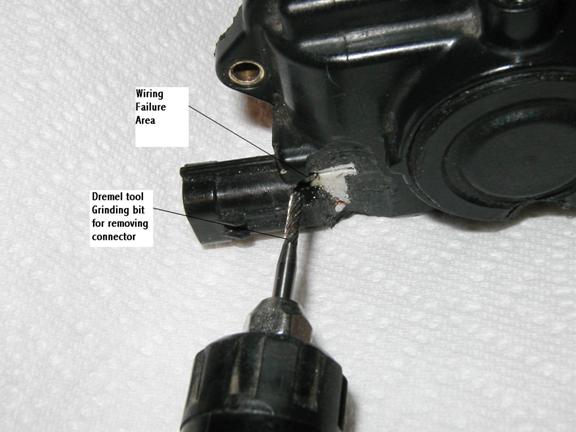

pins. Therefore, I decided to delicately

grind into the rear of the connector, planning (ok, hoping) to locate the

coil wire connections without destroying them.

I used a Dremel tool with a 3/32nd

spiral grinding bit.

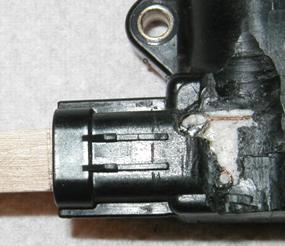

The first thing I did was decide how far back from the edge

of the connector to start grinding. I

measured the inside depth (Popsicle stick pic) from

the outside end of the connector edge to the bottom of the pins. This was about ½”. I added ¼” for connector pin potting material

in the body and decided the rear of the pins were “probably” about ¾” from

the outside edge of the connector. (Sorry, these pictures were taken after

the process, as I did not know at the time I would write this article)

I was unsure how the wires

exited the back of the connector pins so I started grinding about 1” back

from the outside edge, taking small amounts of material at a time and watching

closely for different material. I

used a 10X magnifying visor for better visibility.

This process takes patience and a little luck. When I found a cavity or change in material

type, I took a small metal pick and removed bits of material to investigate

before grinding further. After I exposed

both wires, I was able to determine using the ohmmeter which one was at fault.

I found the inboard “connector pin to wire” connection had failed.

By grinding and picking my way down to the brass pin, I was able to

clear space on the back of the pin and solder the coil wire back to the pin. This connection may have originally only been

crimped. For that reason, I have a

hunch many Miata ISCVs

fail this same way.

This was the resistance reading

after the repair was completed. Keep

in mind I have about 1 ohm resistance in my test leads. Therefore, the actual reading is about 12.2

ohms.

All

that was necessary to put this ISCV back in service was to seal the “disturbed”

area with High Temp. Black Silicone sealant. The resulting ISCV is probably “Better Than New” as a used car salesman friend used to say. NOTE: There is no need to remove this

Solenoid module from the body of the ISCV to attempt this repair. It is only removed in these pictures because

I had removed it as part of the following article section.

VALVE OPERATION / CONSTRUCTION:

This

valve is a rotary solenoid with a flat coil return spring. The armature of the solenoid is pressed onto

a rotating shaft carried by two precision bearings. Between these two bearings is what I will call

a cylinder segment plate or shutter. This

shutter sits behind a matching curved window in the body of the ISCV. This shutter adjusts idle air/rpm by rotating

clockwise (CW) (viewed from spring end of shaft) off its stop and metering

bypass air into the IM. The (ECU) controls

the current through the solenoid coil and thereby the CW rotational force

applied to the valve shaft. The return

spring opposes this CW rotating force with a CCW force. Where the two forces equalize is where the shutter

sets in the window and determines the amount of idle air bypassing the TB

butterfly valve. When no power is applied

to the solenoid (connector removed) the shaft is rotated CCW by the return

spring and the shutter rests against a stop screw. In this “no power” or at rest position the valve

allows “approx” 20% of the air it would pass if fully open. This explains why removing the connector at

idle normally causes an increase in idle rpm.

Here

are a series of photos of the separate parts.

This is the ISCV body with

all parts removed. The top of the body

in this picture is where the solenoid module is nested and attached with 3

screws.

This is the ISCV shaft. From the left, the primary parts pressed or

welded on the shaft are:

The highly magnetic solenoid

armature cylinder, next, a short brass spacer, next, the small bearing, next,

the shutter valve plate (spaced off the shaft), next, the larger bearing (labeled

Japan NTN 635Z) and then a small brass ring pressed on the right end.

This is a view of the “bottom”

or hidden side of the solenoid module, which mates to the metal valve body.

You can see the coil location and the stator arms that bring the magnetic

field from the coil to the armature core on the shaft.

Barely visible in this picture is a rubber gasket that goes around

the outer perimeter on this surface of the module and seals it against the

metal valve body. NOTE: Three screws attach this module

to the metal body. Only one of these

screws is visible when the unit is fully assembled. The other two are hidden inside under the Return

Spring. You can see where they pass

through the metal stator bars in the picture above.

These

are the major parts that make up the ISCV.

They are oriented as they would be if they were assembled. NOTE: The white ring on the end of the

valve shaft is the Return Spring. See

the next picture for a better look at this spring when it is removed from

the shaft. Also notice this view looks

into the “Return Spring Set Screw Hole” on the outer circumference of the

black solenoid module. I strongly suggest

that this screw not be turned. There

is surely a factory pre-set tension applied to the return spring. That correct pre-set tension

will likely be lost if this screw is backed out even a few turns. That pre-set CCW tension would be critical to

resist the CW rotation of the valve shaft when current is applied to the solenoid

by the ECU.

This

is the Return Spring and the white ring that is molded onto it’s

outside end. The silver component is

a return spring to shaft adapter that slides onto the valve shaft. Notice the offset slot is where the inside spring

end sets when installed on the shaft. Also

be advised there is an internally toothed spring washer that goes on the end

of the shaft to hold the items in place.

Here

are a few other Misc. views of the ISCV parts.

This view is looking into

the end of the shaft hole where the larger shaft bearing seats on the side

of the body opposite where the solenoid module sets. Also notice the Shutter

valve Stop screw appearing in the left side of the hole just beyond the bearing

seat. The shutter plate rests against

this screw when no power is applied to the solenoid and the return spring

pre-tension sends the valve to this location.

Also notice visible on the other end of the shaft hole is the smaller

hole where the shaft and armature exit the body. Remember that the smaller bearing is on the

shaft on that side of the armature and essentially seals off that upper hole.

This view is looking into the two rectangular

air outlet ports on the side of the ISCV that mate to the TB. These ports are isolated from one another and

the coolant passages (far left) by the special O-ring gasket sandwiched between

the ISCV and TB. In the back of the right port (the Warm idle port)

you can see the shutter valve installed (see armature at top where solenoid

module would be attached). The

valve in this picture is resting against the stop screw out of sight on it’s

right. Notice the valve is actually

open in this position approx 20%. This

is the no power, failed open coil, or connector removed, position of the valve. Note that from here the valve shutter can only

move/rotate to the left (CW, from above) and must pass through the actual

valve closed, no air position to get to the normal operating positions

where it operates when driven by the ECU.

If the engine dies at warm idle and the ISCV is dirty, the shutter

is probably stuck in the closed area.

This picture shows the valve rotated CW off the stop screw

and past the fully “closed” position. This

position is much as it might be during normal operation.

The left air passage is the Cold idle

port and leads through an isolated passage in the TB and IM to the AV and

back into the IM, causing the idle to be higher during warm-up. This port is not controlled by the shutter valve

but should only have air flowing through it until the AV warms to operating

temperature and fully closes.

This

is a shot of a few parts that were not shown or not clearly visible in other

pictures. Upper left is the retaining

spring washer that is installed next to the return spring shaft adapter on

the valve shaft. Next, to the right

is the spring to shaft adapter. This

shot shows the offset slot where the inner return spring end sets. Also on the opposite surface is visible a larger

center slot that mates with flat surfaces on the sides of the valve

shaft at the spring end. Below that

is the rubber perimeter gasket mentioned but barely visible on the solenoid

module. To the left of that is the

special O-ring gasket that is sandwiched between the ISCV and the TB. You can see that the air outlet passages (cold

& warm) are isolated from one another.

What

may be of interest is that the two left hand coolant ports are not isolated

from one another. If you look above

at the picture of the metal body you’ll see the coolant outlet tube

is connected to the lower hole. The

coolant comes through the valve body and exits at the upper hole. No isolation is apparently needed because the

coolant only makes a “token” trip into the TB before immediately coming back

into the ISCV and passing out the lower tube to the AV.

CREDITS:

The written references I used for this article

were the 1993 Mazda MX-5 Wiring Diagram and the 1993 Mazda MX-5 Workshop Manual. I also want to thank Bill Strohm

as a considerable resource for answering questions during my troubleshooting

phase and during the writing of this article.

Also, there were numerous Miata.net forum posters that influenced my

successful outcome. Kudos to them all!

Comments from Jur:

The article on the ISCV is very clear and helpful. it helped me to get to the culprit of *very high* CO on mu 1991 NA 1.6. that was caused by clogged coolant lines that run through the ISCV and the cold idle valve. maybe you could add that as a point of interest. these cars are getting older and clogging of thes very thin lines might occur more and more.

| [Home] - [FAQ] - [Search] - [Sponsors] - [Forums] |

| [Garage] - [Clubs] - [Contact Us] - [Disclosures] - [More...] |

Copyright

©1994-2024, Eunos Communications LLC

|