Some '99 and '00 Miata's are afflicted with the "mis-machined #4 main bearing cap" and there is a lot of misinformation and associated panic because of it. The Mazda technical service bulletin is listed at Miata.net.

I feel the general failure description is actually incorrect and a misnomer since the engine failure is caused by the thrust bearing itself (which resides in the #4 cap block support) from being too thin/narrow. The #4 cap block support was machined with a too deep thrust bearing recess and when the factory then installed the standard thrust bearing size it was subsequently too thin. The too narrow thrust bearing in some engines leads to very premeteur engine wear and eventually a catestrophic failure.

The 99 caps I have are identical in every way to the 1.6 and M1 1.8 caps I have so I drew the conclusion that Mazda installed too thin of thrust bearings. If, on the other hand, the factory intended to use thinner thrust bearings all along and the supplier incorrectly machined the block to the deeper thrust bearing landing of the 1.6/M1 1.8 specs then the factory TSB description of "mis machined #4 cap" fits.

Mazda's solution to this is to warrantee a whole new engine if there is a problem with an individual engine. Not all engiens are affected. Many people, however, have gone into dealerships demanding a new engine because their VIN number fell into the effected range when, in fact, their engines were just fine.

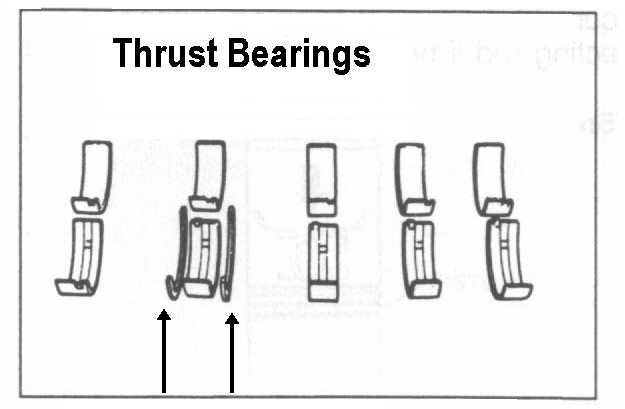

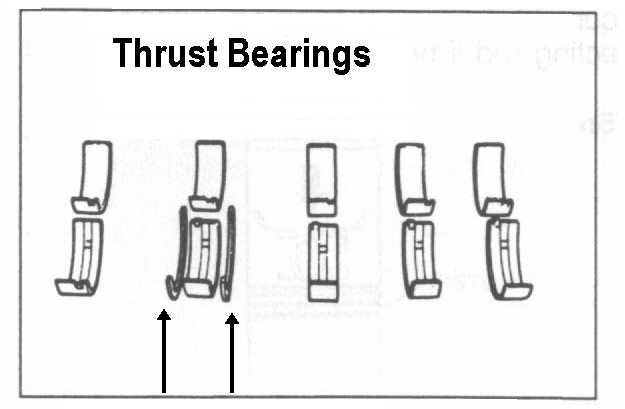

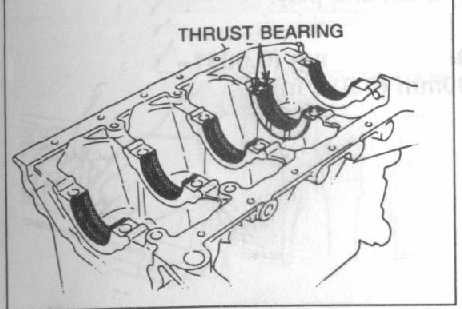

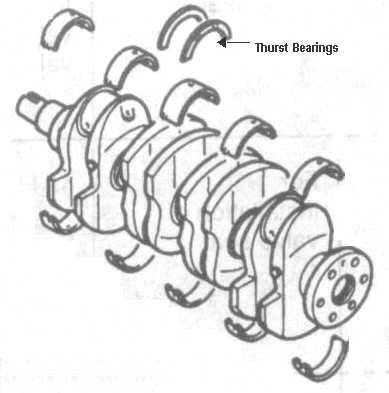

Thrust bearings. click for larger image

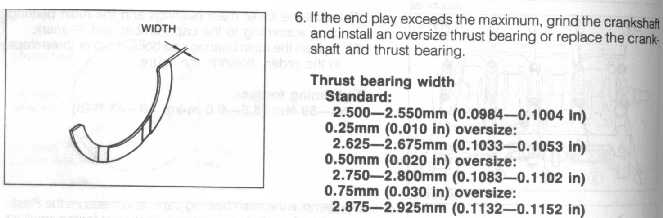

The engines are destroyed by a self-machining process which adds metal shavings and metal powder to your oil. Thrust bearings come in 4 thicknesses from the factory; 2.5mm, 2.625mm, 2.75mm and 2.875mm. Thrust bearings that were too thin were installed in a batch of engines regardless of what was required (that is why not all engines are affected, some needed the thinner bearings anyway). For those engines that required a thicker thrust bearing installed the greater tolerance allowed the crankshaft to move backwards and forwards to the point where the thrust bearing itself starts to have accelerated wear. (Most automatic equipped engines will not suffer any ill effects of a too small thrust bearing because automatic transmissions don't put any fore and aft load on the crankshaft like stick shifts do).

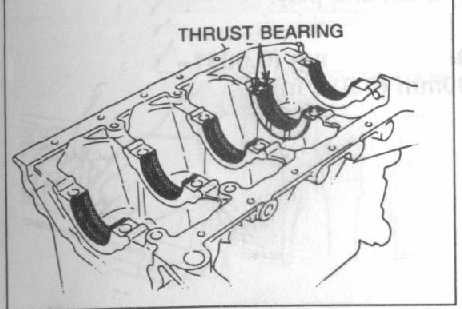

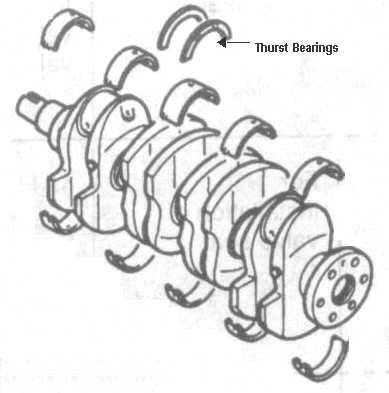

Thrust bearings.click for larger image

Thrust bearings.click for larger image

Once the thrust bearing has worn to a sufficient thinness the crankshaft will actually come in contact with the block and the main bearing caps and will start to self-machine them. The crankshaft is a far harder steel material than the cast iron block and caps so they loose this battle.

Compare normal main bearing caps with ones machined by the crank. click for larger image

Compare normal main bearing caps with ones machined by the crank. click for larger image

The block also gets grooves cut in it usually making it unusable. click for larger image

The block also gets grooves cut in it usually making it unusable. click for larger image

You can tell if you have an effected engine by checking the crankshaft endplay. This can easily done by *lightly* (it doesn't take much force) prying on the crankshaft pulley and seeing if it moves fore and aft.

The affected 99-00 engines were being delivered with .010 - .020" endplay tolerance from the factory. It should be no greater than .006" new. It is my recommendation that anything more than about .008" - .010" cold on a fairly *new* engine and you should be concerned. Mazda recommends .3mm (.0118"). If your endplay is less than .008" cold then forget about it and just drive the car.

After the thrust bearings have been worn enough they will be actually thin enough to fall out of their landing. Sometimes you get lucky and they fall directly into the oil pan, other times they bounce around for a while and mangle most everything, which means, even with a rebuild, you will likely have to get new pistons and rods too. But that has little meaning anyway since, without thrust bearings, the crankshaft can move 1/4" (which is why people report less clutch travel as a symptom) and nothing will hold it back from machining all in its path. In extreme cases rods have even broke because they are now out of alighnment with the cylinder bore.

Without a thrust bearing the crankshaft can move up to 1/4".

Without a thrust bearing the crankshaft can move up to 1/4".

Q:

My 99 engine has XX,XXX miles on it. I just checked the endplay and it is fine now but do I have to worry about it in the future.

A:

No. In my opinion, if your engine is past 20K miles then you are past the point when the failure would have likely happened. All failed 99 engines I opened up were under 12K. If your endplay is fine now and there is no excessive endplay to allow an accelerated wear then your engine will likely live a normal life span. Don't go by milage alone though as there are just too many variables. I recommend to change your oil religiously and open your hood and check the endplay every now and then. Doesn't take more than a few minutes to do.

Q:

Is there a way to mic / measure the #4 thrust/main bearing support & recess area (where thrust bearings are fitted) and the thrust

bearing thickness to determine the correct / appropriate guage bearing

required?

A:

Not without dropping the oil pan, which requires lowering the subframe. Just use the endplay measurement. Provides the same results.

Q:

Is there an aftermarket 'saddle' type bearing retro-fit available?

A:

No. The issue has nothing really to do with the design of the thrust bearing being a shim style or a saddle style. While it is true a saddle style would not allow the thrust bearing to fall out when it got too thin, but it would still wear at the same accelerted rate if the endplay was too wide.

Q:

How reliable is the end play measurment in determining durability?

A:

Very. It is the sole determining factor other than oil change intervals. If your endplay is fine the then motor is in spec.

Q:

Is the end play measurment a fool proof way to verrify the correct thrust bearing selection?

A:

Yes. Change your oil regularly. That is the best way to keep the thrust bearing clearance from growing.

Q:

My concern is that if I take this reading now (engine in car), and it is less than .008", excessive end play (+.010") could show up any time after.Is the case true?

A:

No! If your endplay if fine now IT WILL NOT grow beyond a normal growth rate as long as you change the oil regularly.

Q:

My car is past warrantee and my crankshaft endplay is probably 1/16" - 1/8". Is the engine repairable?

A:

Maybe...maybe not. Depends on how quick you caught it.

In any case, you will need to remove the oil pan and inspect the thrust bearings, block, #4 main cap to make a determination.

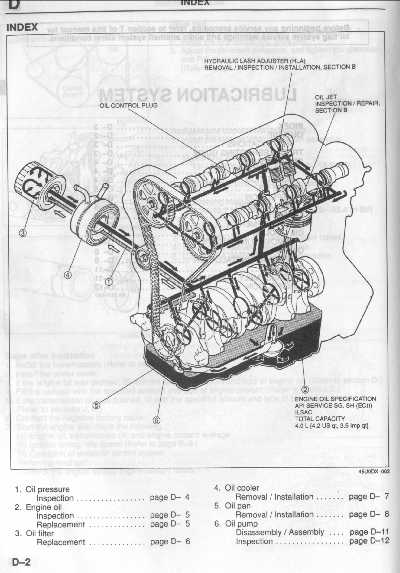

1.6 and 1.8 'B' oil system. click for larger image

1.6 and 1.8 'B' oil system. click for larger image

Let me know what you think about my page. Send mail by clicking here.